Innovation and Sustainability: Custom Ambulance Design

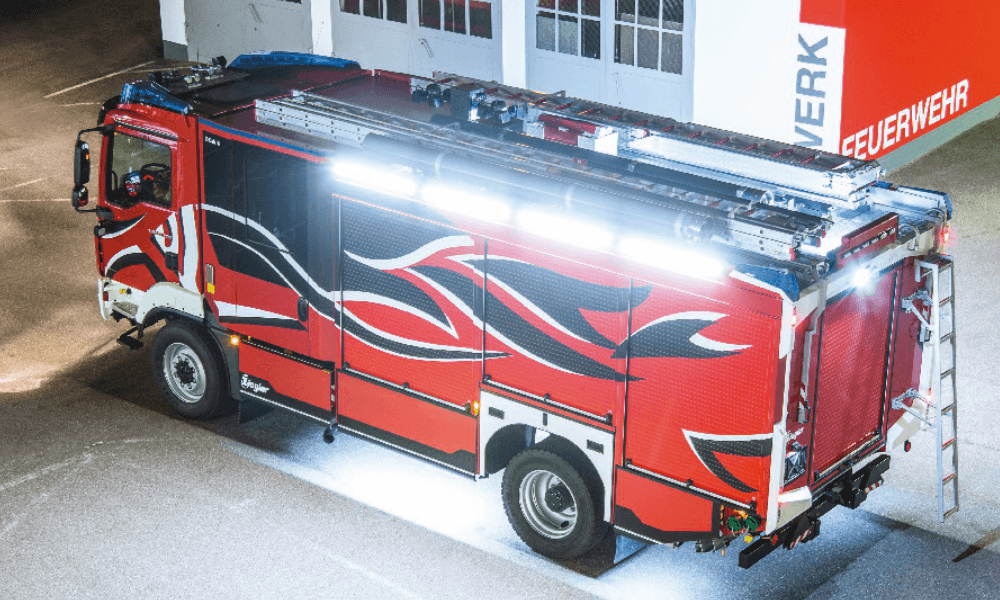

As part of this custom project, this case study showcases how tailored solutions can enhance both functionality and aesthetics in emergency vehicles. This custom project is dedicated to providing innovative and sustainable designs that improve performance and efficiency.

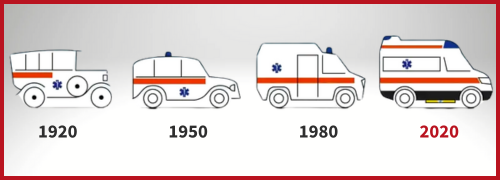

The Evolution of Ambulance Lighting

Ambulance design is evolving. Increasingly, manufacturers are moving away from bulky light bars and opting for custom spoilers that seamlessly integrate lighting into the vehicle’s aerodynamics. But this shift isn’t just about aesthetics; it’s driven by real performance needs.

🚀 A unique, modern look – Custom spoilers help emergency vehicles stand out while maintaining a professional and cutting-edge appearance.

🌱 Better aerodynamics & sustainability – By reducing wind resistance, these spoilers lower fuel consumption and cut down on noise pollution.

Simply put: good design is smart design.

The Problem with Traditional Light Bars

While traditional light bars have served their purpose, they come with their fair share of issues:

- ❌ Clunky aesthetics – A standard light bar often disrupts the sleek design of modern ambulances.

- ❌ Increased fuel consumption – High-speed air resistance creates drag, making vehicles less fuel-efficient.

- ❌ Annoying whistling noise – The air passing through traditional bars generates unwanted sound, contributing to noise pollution.

Our challenge? Find a solution that combines sleek design, high performance, and sustainability.

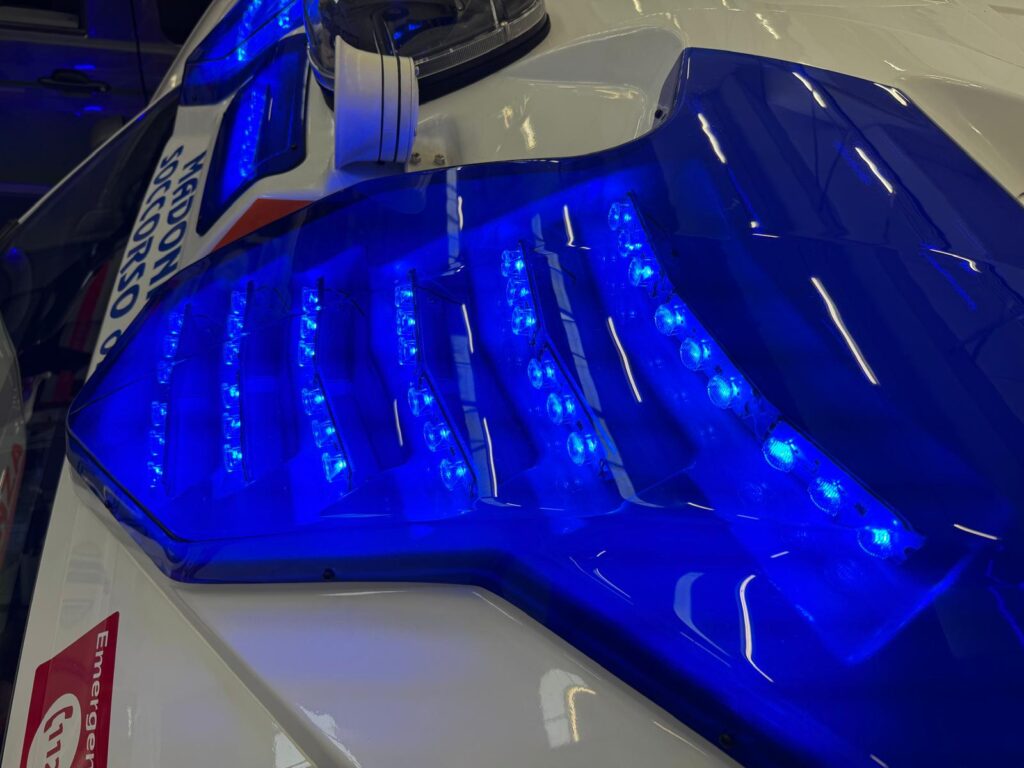

Our Custom Lighting Solution

We recently teamed up with a client to integrate our advanced LED lighting modules into their new custom ambulance spoiler. This wasn’t our first collaboration—they had already trusted us for interior lighting in special vehicles.

But after seeing our lighting system in action on an ambulance for a leading Italian manufacturer, they knew we were the right partner to push their innovation further.

🔹 Integrated blue power LED modules – Designed for maximum visibility and efficiency.

🔹 CAD-designed components – Every detail was mapped out for a perfect fit.

🔹 Seamless aerodynamics – The lighting is fully integrated into the spoiler, eliminating drag.

Because when every second counts, lighting should be powerful, efficient, and built to perform.

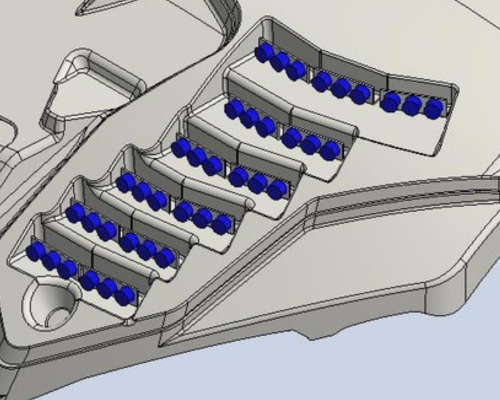

From Concept to Reality: The Development Process

- 🔍 Step 1: Understanding the Client’s Needs – We started with an on-site consultation to analyze requirements and identify the best approach.

- 🖨️ Step 2: 3D Printed Prototypes – Before moving to production, we developed a 3D-printed model of the LED modules to refine the design and ensure perfect integration.

- ⚙️ Step 3: Optimization & Testing – We fine-tuned the external blue power LED lights, balancing functionality with aesthetics for a sleek, high-performance solution.

- 🚀 Step 4: Final Implementation – Working closely with the manufacturer, we seamlessly integrated the new lighting system into their ambulance design—creating a spoiler that’s as efficient as it is innovative.

A Step Towards Innovation

This project is more than just a technical achievement—it’s a statement.

Customization isn’t just about making vehicles look good. It’s about making them perform better, last longer, and operate more efficiently.

And when innovation meets real-world functionality, everyone wins—from manufacturers to first responders to the people they help every day.